charpy impact test notch facing|charpy v notch test procedure : purchasers The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . WEBCompartilhe a experiência que teve com DISMEF DISTRIBUIDORA DE MATERIAIS ELETRICOS HIDRAULICOS E FERRAMENTAS. Rated 0 stars out of 5. sim não Ligarei mais tarde. Tel: (19) 3278-40. Confira o telefone, endereço, formas de pagamento, avaliações, fotos, redes sociais, site e outras informações complementares.

{plog:ftitle_list}

WEBEncontre livros de diversos temas e autores no Clube de Autores, uma plataforma de venda online de livros digitais. Pesquise por categoria, ordenação, preço e versão, e .

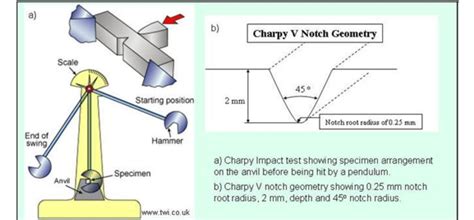

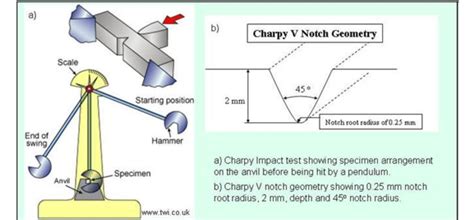

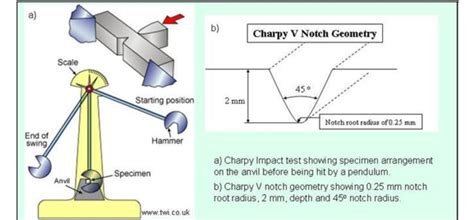

The testing apparatus consists of a weighted hammer mounted at the end of a pendulum. The hammer can be raised to a known height and the sample to be tested placed in the path of the . In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge .

The Charpy impact test, also referred to as Charpy v-notch test, is a materials testing method used to determine the impact strength of materials using a pendulum impact tester.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces.

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .

What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy . To successfully perform a Charpy V-notch impact test, the following steps must be followed for accurate results: 1. Notch test specimens . Next, place the specimen horizontally in the anvil at the lower part of the .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which . • Using the tongs, quickly remove the test specimen from the bath and place it on the test fixture with the notch opening facing away from the direction of the cocked pendulum • Stand clearThe test specimen is clamped into the vice in a position so that the notched end of the specimen is facing the striking edge of the pendulum. A properly positioned test specimen is showed in the following figure. . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss

This puts the side with the notch into tension, causing an initiation of fracture from the notch. Figure 2 Charpy Test Specimen under Load. The most commonly used specimen, the Charpy V-notch (CVN), is 10 × 10 × 55 mm and has a V-notch 2 mm deep with a 0.25 mm tip radius.

iphone 6s zagg shockguard drop test

charpy v notch toughness

CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . Specimen Position Horizontally, Notch facing away from the pendulum Vertically, Notch facing towards the pendulum Point of Impact Middle (center) of the sample Upper Tip of . IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally .

The test specimen is clamped into the vice in a position so that the notched end of the specimen is facing the striking edge of the pendulum. A properly positioned test specimen is showed in the following figure. . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, tossThe ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact test where a weighted pendulum hammer is released from a specified height and strikes the part. A Charpy impact testing apparatus, a .

Plastic V notch impact sample 80*10*4mm Organic glass V notch impact sample 80*10*4mm . By testing plastics with the Charpy test method the impact resistance of the plastic can be determined. Charpy impact testing can also be used to determine the sensitivity of notched plastics specimens. Impact resistance of plastic notched specimens measures .

Charpy Impact Test unit with the notch facing the direction of the pendulum impact, and the pendulum is released. When the pendulum hammer breaks the specimen, a portion of its kinetic energy will be absorbed by the deformation process; therefore, the pendulum would not swing as high on the other . Cutting the specimen is the second step in preparing U- and V-notched specimens for Charpy and Izod impact testing. The material is precisely cut into standardized dimensions during this process. Standard Dimensions. Charpy Test Specimens: Length: 55 mm. Width: 10 mm. Thickness: 10 mm. Izod Test Specimens: Plastic Specimens: 64 mm x 12.7 .How is the Charpy impact test performed? Select one: The Charpy impact test specimen is held vertically with the notch facing the pendulum. The Charpy impact test specimen is held horizontally with the notch facing away from the pendulum. The Chary impact test specimen is held horizontally with the notch facing the pendulum • The Charpy .

The test specimen is clamped into the vice in a position so that the notched end of the specimen is facing the striking edge of the pendulum. A properly positioned test specimen is showed in the following figure. . Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .

The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . However, in the context of an impact test we are looking at notch toughness, a measure of the metal's resistance to brittle or fast fracture in the presence of a flaw or notch and fast .

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .Charpy and Izod Impact Testing The Charpy or the Izod impact test is carried out by testers using a pendulum impact testing apparatus. A device having a swinging pendulum that is released to strike a secured specimen is referred to as a pendulum impact testing machine or a pendulum impact tester. A weighted hammer on [.]

charpy v notch testing standard

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and materials development. . quickly remove the specimen from the liquid bath and place it on the Charpy test fixture with the notch opening facing away from . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, Notch facing towards the pendulum. Point of Impact. Middle (center) of the sample. Upper Tip of the sample. Common Specimen . Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. . In the DWT test the crack inducer is a bead of hard-facing metal around 76 mm long. The sample, 89 mm × 356 mm × 19 mm, is placed weld down, on .The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the .Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

iphone 7 100 feet drop test

WEBVirtual Succubus Feburary 2024 - Voiced Orders & Conditioning$10. Virtual Succubus is a deeply customizable Jerk Off Instructions experience with your personal Femdom AI.

charpy impact test notch facing|charpy v notch test procedure